Insulation Foam

Products list

Clients

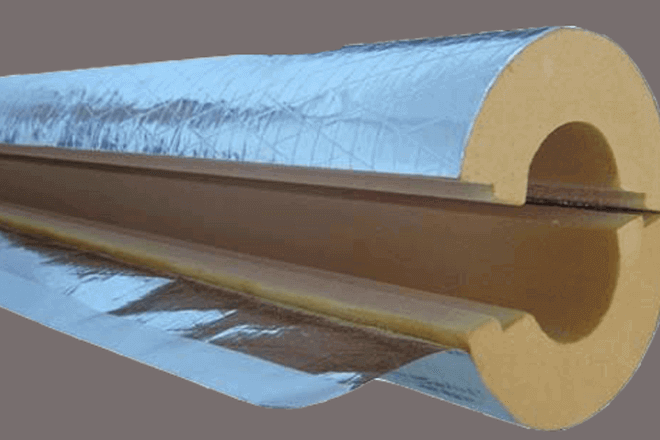

Insulation Foam (Phenolic foam)

VND Phenolic foam is a light weight, easy to handle, ideal for varieties of uses in insulation across a range of applications. Phenolic foam is a rigid Cellular foam product with a closed fine cell structure, whose polymer structure is made of poly condensation of phenol and aldehydes.

One of the most widely used product in residential, commercial and industrial construction, It is also used in Naval, aerospace, Defence applications.

The fire performance of VND phenolic foam { Insulation Foam} is exceptional. It combines zero or very low flame spread with negligible smoke emission and a very low level of toxic gas emission.

In addition, VND Phenolic foam evolves exceptionally low smoke when exposed to fire and is capable of meeting or exceeding all international building regulation requirements. Toxic gas emission from phenolic foam is generally limited to carbon dioxide and carbon monoxide with very low levels of other gases.

VND phenolic foam offers a significantly better insulation performance than all other insulation materials providing an energy saving benefit and lower long term system running costs.

VND Phenolic foam is also used in a number of high specialised applications including fire doors, highly fire resistant panels and for insulation in surface ships, off-shore installations and submarines.

Insulation Foam Properties

- Phenolic foam has very low embodied energy per unit thermal performance compared to other insulation materials

- Significant energy savings can be achieved compared to other insulation materials

- VND Phenolic foam is manufactured entirely without CFC/HCFC blowing agents.

- Phenolic foam has been used successfully in insulation systems where moisture resistance is a key issue

- Phenolic foam has a low water vapour presence and is therefore highly resistant to the passage of water vapour

- VND Phenolic foam has extremely fine cell structure and more than 90% closed cell structure.

- High density phenolic foam has very good structural properties and such can be used for pipe and duct supports.

Phenolic foam has been used successfully in insulation systems where moisture resistance is a key issue.

Features Include :

- Excellent fire resistance performance

- Low smoke emission

- High temperature resistance & stability

- Superior thermal performance

- Extremely sound insulting property

- Structural strength performance

- Moisture resistance performance

- Chemical Resistance and compatibility performance

- A wide service temperature range between -196 deg C to +130 deg C

TYPICAL APPLICATIONS :

- Ducting, piping, roofing insulation in following industry.

- Textiles

- HVAC Industry

- Food Processing

- Pharmaceutical

- Hospitals

- Suspended ceilings and roof insulation for commercial complexes, residential buildings, Industrial buildings and structures.

- Insulation of high altitude shelters and ships

- Refrigerated containers

- Cold store panels

- Petrochemical and Gas processing

- Life saving equipment such as life jackets, buoyancy block and other marine equipments

PRODUCT RANGE :

| 1 | Blocks form | Any specified size |

| 2 | Slabs | |

|---|---|---|

| Size | 1) 1220 x 610 mm | |

| 2) 1195 x 595 mm | ||

| 3) 1000 x 500 mm | ||

| 4) Any other customised size | ||

| Thickness | Any specified thickness | |

| Facings | Kraft paper, Aluminium foil, Stucco foil, Decorative paper And Gloss cloth. | |

| 3 | Pipe Sections | |

| Size | Nominal Bore 0.25 inch to 20 inch | |

| Thickness(mm) | 25,30,40,50,60,75 & 100mm | |

| Facings | Bare, Aluminium foil and Gloss cloth. | |

TECHNICAL DATA :

| PHYSICAL PROPERTIES : | |

|---|---|

| Colour | Green or any other specified colour |

| Density | 30 to 45 kgs/m3 or any specified density |

| MECHANICAL PROPERTIES : | |

| Compressive Strength | 120 to 190 KN/m2 |

| Tensile Strength | 220 to 250 KN/m2 |

| Cross Breaking Strength | 220 to 250 KN/ m2 |

| Shear Strength | 100 to 140 KN/m2 |

| THERMAL PROPERTIES : ( BS:4370) | |

| Thermal Conductivity | 0.018 to 0.022 W/mtr.degK |

| Temperature Limits | -180 deg C to 120 deg C |

| Dimensional Stability | < 2% (BS: 3927) |

| MOISTURE PROPERTIES | |

| Water Vapour Transmission | < 2 perm inch |

| Water Propagation ( ISO:2896) | < 5% W/V |

| FIRE PROPERTIES : | |

| Ignitability, BS:476 part – 5 | Class – P |

| Fire Propagation, BS:476 part – 6 | S < 12 |

| Surface Spread of Flame, BS:476 part-7 | Class I |

| Building Regulations | Class 0 |

| Critical Oxygen Index | 45 |

| Smoke Index | <5 |

| Punking Behaviour | Non – Punking |

| Toxicity Index | <5 |

| Closed Cell Content | 90 % plus. |